Nome chinês de PVC: 聚氯乙烯

Nome da mercadoria: Plástico PVC, Plástico de cloreto de polivinila

Cloreto de polivinila

Cor: Translúcido amarelado, brilhante

Ponto de fusão: O PVC é um polímero amorfo, não há ponto de fusão óbvio e o aquecimento a 120 ~ 150℃ apresenta plasticidade.

Plástico de cloreto de polivinila

Propriedades físicas e químicas do plástico PVC:

O PVC é um material polimérico que usa um átomo de cloro para substituir um átomo de hidrogênio no polietileno. O material de PVC é um tipo de material plástico, que é feito de resina de cloreto de polivinila como principal matéria-prima, adicionando uma quantidade adequada de agente antienvelhecimento, modificador, etc., por meio de mistura, calandragem, blister a vácuo e outros processos. A transparência do PVC é melhor do que o polietileno, polipropileno, pobre em poliestireno, com a quantidade de aditivos é diferente, dividido em cloreto de polivinila macio e duro, os produtos macios são macios e resistentes, parecem pegajosos, a dureza dos produtos duros é maior do que o polietileno de baixa densidade e menor do que o polipropileno, na dobra aparecerá o fenômeno de branqueamento. Produtos comuns: pratos, tubos, solas, brinquedos, portas e janelas, pele de arame, artigos de papelaria e assim por diante.

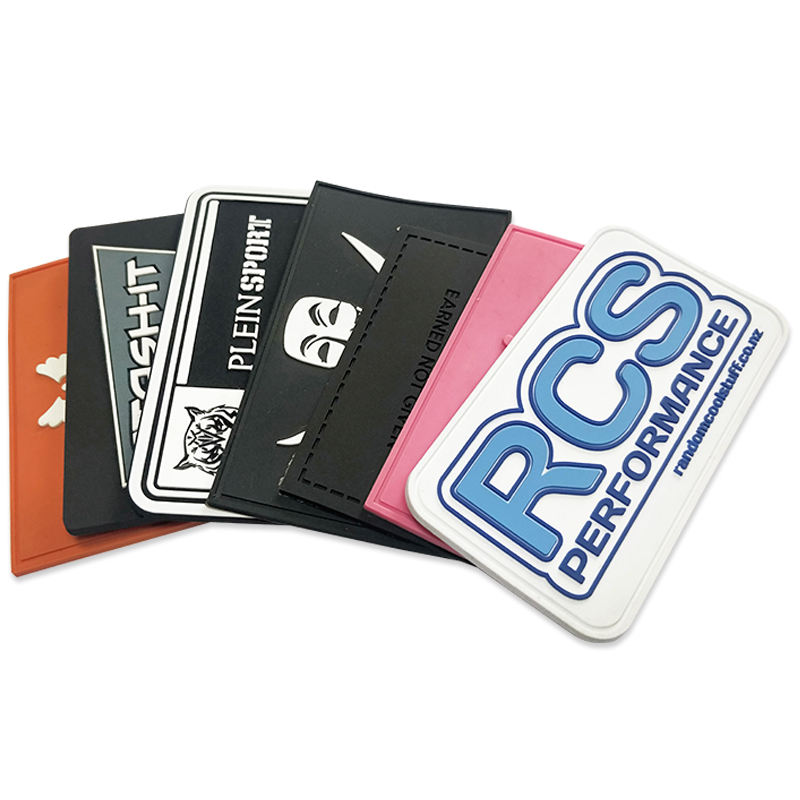

Etiqueta de borracha de PVC

Os produtos de PVC têm estabilidade química e forte resistência a oxidantes, agentes redutores e ácidos fortes. No entanto, podem ser corroídos por ácidos oxidantes concentrados, como ácido sulfúrico e ácido nítrico, e não são adequados para contato com hidrocarbonetos aromáticos e hidrocarbonetos clorados.

Produtos de PVC

O PVC tem as vantagens de resistência à chama, resistência ao desgaste, amortecimento de ruído, alta resistência, bom isolamento elétrico, baixo preço e ampla fonte de materiais, bom desempenho hermético e assim por diante.

A Desvantagem do Pvc É Que O Desempenho De Estabilidade Térmica É Pobre, Fácil De Envelhecer Pela Luz, Calor E Oxigênio. A Temperatura De Uso De Longo Prazo Da Maioria Dos Produtos Plásticos De Pvc Não Deve Exceder 55℃, Mas A Temperatura De Uso De Longo Prazo Do Plástico De Pvc De Fórmula Especial Pode Chegar A 90℃.

Além disso, o PVC é geralmente considerado tóxico. A resina de cloreto de polivinila em si não é tóxica, se o uso de plastificante não tóxico, estabilizador e outros materiais auxiliares feitos de produtos, inofensivos para humanos e animais. No entanto, os pequenos produtos de PVC comuns no mercado usados no plastificante, estabilizador, a maioria é tóxica, portanto, além da fórmula não tóxica dos produtos, não podem ser usados para alimentos elegantes.

As vantagens de Etiqueta de PVC Impressão:

O PVC tem não inflamabilidade, alta resistência, resistência a mudanças climáticas, excelente estabilidade geométrica e forte resistência a oxidantes, agentes redutores e ácidos fortes. Além disso, devido à sua boa flexibilidade, encolhimento, permeabilidade à luz, bom desempenho de processamento e rotulagem, forte resistência à corrosão química, firme e durável, portanto, adequado para uso externo de longo prazo.

No entanto, o PVC tem baixa estabilidade térmica e resistência à luz e pode começar a se decompor e liberar gás cloreto de hidrogênio (HCl) acima de 140℃, o que não é propício à proteção ambiental (na produção real, estabilizador alcalino e Hcl são frequentemente adicionados para inibir sua reação de craqueamento catalítico). Além disso, plastificantes, agentes antienvelhecimento e outros materiais auxiliares tóxicos são adicionados no processo de fabricação para aumentar a resistência ao calor, tenacidade, ductilidade, etc., portanto, seus produtos geralmente não são armazenados em alimentos e medicamentos. Além disso, a degradação do material do rótulo de PVC é ruim, o que prejudica a proteção ambiental.

A aplicação comum da impressão de etiquetas de PVC

O PVC tem excelente desempenho de entintamento e pode ser feito em uma variedade de cores, uma ampla gama de aplicações. É adequado para etiquetas com requisitos de alto desempenho, como resistência à água, óleo e produtos químicos, e devido às suas propriedades flexíveis, é comumente usado em suprimentos de banheiro, cosméticos, produtos elétricos e joias, joias, relógios, eletrônicos, metais e outras ocasiões de alta qualidade.

Além disso, a etiqueta adesiva de filme retrátil de PVC é adequada para etiquetas especiais de marca registrada de bateria.